- Business field

- UV sterilizing device

UV sterilizing device

We can manufacture the high-capacity sterilizer without reduction in its sterilizing effect. The precedent high-capacity sterilizer should be used with parallel connections, leading to much space occupation for its installation and its difficult maintenance and management. On the other hand, this one resolves all the said problems of its precedent.

Drinking water sterilizing area

Chlorination treatments used for the purpose of sterilization after purification of tap water have the advantage of being able to achieve sterilizing purposes at the cheapest cost and retain sterilizing power during transport process. So it has contributed greatly to the prevention of waterborne epidemic and the improvement of hygienic condition, but case of drinking water directly is rare due to the bad taste peculiar to disinfectant, and it has discomfort to go through water-purifying device with a carbon filter, or boiling before drinking.

Various problems of using disinfectants in sterilizing process are being reported, and in a world-widely authoritative journals, there are 1,600 presentations of research paper about

In addition, saying that it is safe and good to directly drink tap water that contains disinfectant, the public officials of the Ministry of Environment, the department having chief control of relating laws, has an ambivalent attitude to drink bottled water instead of the tap water.

sewage, effluent water sterilizing device

Using disinfectants to sterilize the effluent of sewage treatment plant makes the disinfectants remain for a period of time, and it destroys the aquatic ecosystem of the lower stream of the outlets of the sewage. Thus, including eco-toxicological standards to the effluent water-quality standards, UV sterilizing device free of eco-toxicology is being used.

Swimming-pool water sterilizing area

Since the swimmer's body contacts directly to the water of swimming pools, users can be infected by water-borne diseases caused by infectious bacteria such as colon bacillus or eye diseases. Although it is regulated by laws to sterilize by circulating ozone or etc. and maintain more than 0.1 PPM of residual chlorine to prevent sharp proliferation of viruses, various problems are occurring in most swimming pools, being operated solely with disinfectant and without pretreatment with ozone or UV sterilizing device due to the cost and operational problems.

Ultraviolet ray sterilization means an inactivation of replication of microorganisms due to the functional damage due to the polymerization of contiguous DNAs when short-wavelength UV is examined by microbes and UV is absorbed.

The sensitivity to UV sterilization has been reported in the sequence of protozoans, bacterium and viruses. UV sterilization is more effective in bacterium or protozoans than in viruses, as high levels of UV irradiation is required to inactive viruses like Adenovirus, which is resistant to UV. In general, it was reported that the protozoans were resistant to chemicals such as chlorine or ozone.

For UV sterilization, protozoans like Cryptosporidium parvum or Giardia is reported to be easily inactivated by UV than viruses or bacterium, resulting in increased use in treatment of sewage and purified water. Also, UV irradiation is reported to be effective in controlling pathogenic microorganisms that are not residual and don’t generate disinfection by-products, and resistant to chlorine.

- Structure of UV sterilization

Typical UV sterilizer device consisted of sterilizing part, where sterilization process is proceeded, ultraviolet lamps, quartz tubes to protect UV lamps in water, a quartz tube-stationary part to fix quartz tubes, inlet and outlet where intake and outflow of water takes place.

Structure and Outline of Integrated UV sterilization Sterilizing part, where sterilizing process is proceeded by the UV irradiated by the UV lamps has the cylindrical pipe shape and inlet and outlet is installed at the side. And at the one end of the sterilizing part, quartz tube-stationary part to fix the UV lamp inserted quartz tube in installed. Over the 100 years since the UV sterilizing device has been develop, initial form is still being used up to now without considerable change in form or shape.

Depending on the processing capacity, UV sterilizer is equipped with one or more ultraviolet lamp to be irradiated sufficient UV light to microorganisms’ sterilization, and has a structural characteristic to be installed entrances and exits. Bulk sterilizer with small penetrating power of short wave UV in water is characterized by decline of sterilizing power, and there is a problem that 100% sterilizing process is difficult due to the presence of the UV irradiation blind spot inside the sterilizer. Due to the fact, the sterilizer is connected only in series or in parallel, so it is known as a high-cost sterilizing technique that makes the installation and maintenance costs increase.

- It is the all-in-one structure that the entrance and exit are placed at the sterilizing part, reducing its sterilizing effect.

Depending on the increase of the capacity of the UV sterilizer, size of the inlet and outlet pipe also increases. As a result, the length of the effective sterilizing part relatively reduces and the time that water stays at sterilizing part, that is UV irradiating amount is lesser than small capacity sterilizer, so bigger the capacity, bigger the decrease of the sterilizing power.

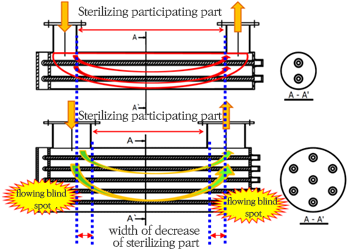

In addition, large capacity sterile devices also have larger diameter of sterilizing part than small capacity sterile devices, and the flow of the water at the ends of the inlet and outlet and in the opposite region, the blind spot of flow also increased where the flow of water is not smooth. (Refer to the picture below)As a result, large sterile devices come have a shorter length of time to participate in sterilization than the small capacity sterile devices as the size of the inlet and outlet pipe is increased, resulting in stagnant fluid flow at the ends of the sterilizing part, thus preventing the entire UV lamp from participating in sterilizing process. Therefore, there is a structural characteristic that the amount of UV required for microbial sterilization decreases, which reduces the sterilizing power.

Decreasing of the sterilizing power with the increasing of the capacity of the sterilizer.

Decreasing of the sterilizing power with the increasing of the capacity of the sterilizer.

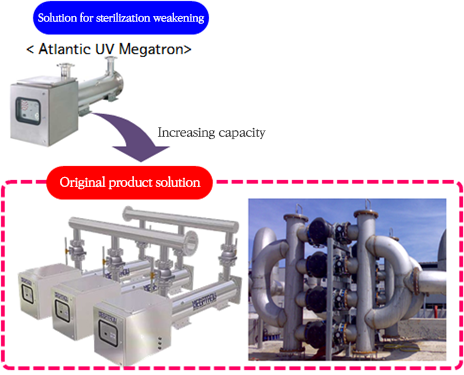

To solve the above problems of decrease of sterilizing power due to the increasing of capacity of sterilizing devices, decreasing of sterilizing power can be minimized by connecting small and medium sterile units with smaller decrease in sterilizing power. But, there are difficulties with keeping up with the increasing costs with the producing of a number of sterile devices, increasing material requirement such as pipes, valves, and attached parts, increasing of installation place and maintenance and control. However, there is no realistic alternatives, so it is being used until now.

It is the parallel-type sterilizer causing reduction of sterilizing effect by increasing capacity of the sterilizer.

It is the parallel-type sterilizer causing reduction of sterilizing effect by increasing capacity of the sterilizer.

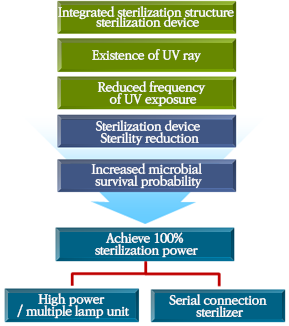

- Impossible of 100% sterilizing treatment with the presence of UV irradiation blind spot

The short-wavelength ultraviolet rays (254 nm), called sterilizing line (salgyunseon), has very small permeable power in the water, so it have a tendency to be transmitted only about a certain distance relative to the intensity in the direction of concentric circle around the lamp. Inside the sterilization unit, there exists a UV irradiation area between lamps, and inside lamp and sterilizing part housing, of where UV cannot be reached.

The underwater microbes that pass through these UV irradiation area are relatively deficient in the amount of UV (strength and frequency) required for sterilization compared to passing through the ultraviolet irradiation fields. Thus, it is difficult to sterilize 100 % by passing through a sterilizing apparatus alive. The use of high-powered ultraviolet lamps or increasing of the amount of using of lamps can minimize the problems caused by UV irradiation blind spot.

A.Increase lamp usage / B.High power lamp / C.Sterilization device series

Weakening of Sterilization by Blined Spots of Ultraviolet irradiation and its solution

A.Increase lamp usage / B.High power lamp / C.Sterilization device series

Weakening of Sterilization by Blined Spots of Ultraviolet irradiation and its solution

- Importance of the 100% sterilizing treatment in UV sterilizing technology

If items undergoing long-term storage or distribution, such as food, beverages and medicines is not 100 % sterilized, the microorganisms must proliferate themselves and decomposed in it, so items will have to be discarded altogether. Therefore, for The UV sterilizer is a device intended for sterilization of microorganisms in water, UV sterilizer that cannot sterilize 100% means lost its function as a UV sterilizer. For this reason, it is meaningless to discuss the excellence of the sterilizer by comparing it with a high and low level of sterilizing ratio, not 100 % sterilization.

Series ultraviolet sterilizer for 100% sterilization

Series ultraviolet sterilizer for 100% sterilization

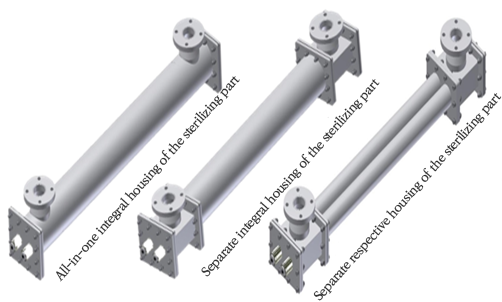

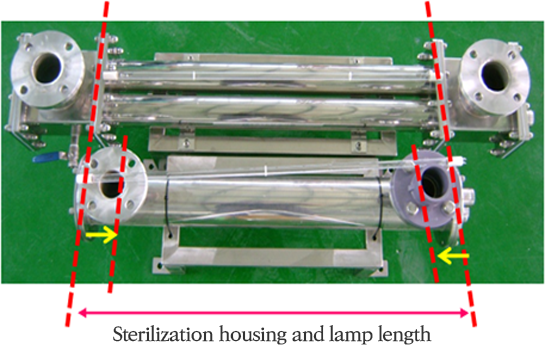

First, isolated the entrances and exits installed on the existing ultraviolet sterilizer and installed the inlet and outlet at the ends of the sterilizing part. So inlet and outlet isolated type sterilizing device that inlet and outlet pipe size does not affect the size of the sterilizing part resolves the problem of the decrease of the sterilizing power due to the increasing capacity.

Second, the problem of ultraviolet irradiation blind spot occurring due to the installation of many lamps in one sterilizing part, was arranged by replacing an UV lamps with individual sterilizing part structure having diameter corresponding UV irradiation distance.

The world’s first developing ultra violet sterilizer system that has no reduction in sterilizing capacity due to the increasing of capacity and UV irradiation blind spot made it possible to acquire patent in United States, China, Japan, UK and certified as performance authentication and excellent procurement item in 2014.

The sterilizer’s structure with 2 ultraviolet lamps for the locations of its entrance and exit and the structure of its sterilizing part

The sterilizer’s structure with 2 ultraviolet lamps for the locations of its entrance and exit and the structure of its sterilizing part

- The cutting-edge ultraviolet sterilizer without blind spots of ultraviolet irradiation and flow

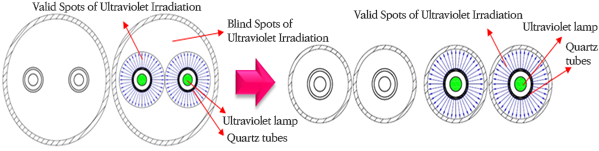

The picture below shows the cross sectional structure of the UV sterilizer with two lamps and the blind spot of UV irradiation present at salgyunbu symbolically. The concentric circle, which connects the penetrating distance of ultraviolet rays around ultraviolet, and outside the concentric circle is marked roughly as a UV irradiation area, and UV blind spot area respectively.

Conventional sterilization device section S & P environment Sterilization device sectionThe realistic method of reducing the square field of ultraviolet irradiation blind spot area by increasing concentric circles that represents the field of ultraviolet irradiation area was possible by increasing the intensity of irradiation by using high-powered ultraviolet lamps in an existing all-in-one structure and the number of ramps, but it is possible in separate individual salgyunbu structural sterilization devices without the increasing of the ramp output and the number of ramps. The section view of the sterilizer having the blind spot of ultraviolet irradiation and the valid spot of it.

The section view of the sterilizer having the blind spot of ultraviolet irradiation and the valid spot of it.

- Comparsion according to each structure of the ultraviolet sterilizer

The following picture contains an existing sterilizing device with a ipchulgu installed in the salgyunbu using two identical lamps, and separate ipchul from salgyunbu and separate structured S&P environmental sterilizing devices with UV lamps having individual salgyunbu. Existing all-in-one structural sterilization equipment has a structure that has shorter length of 살균부 than that of the UV lamps, and separate individual salgyunbu structural sterilization devices can be identified as having the same length in lamp and sterilizing part, and that each lamp has a separate sterilizing part.

To confirm the difference of sterilizing power between existing all-in-one sterilizing device, targeting effluent water of sewage treatment facility containing large amounts of germs, sterilizing power was compared under the same conditions. 2-lamp ultraviolet sterilizer owing to valid/blind spots of ultraviolet irradiation

2-lamp ultraviolet sterilizer owing to valid/blind spots of ultraviolet irradiation

To ensure uniformity of the test, the identical output lamps (39 W) per sterilizing devices, install of the flow meter, and the same flow rate are maintained, and after comparison experiment of sterilizing power in a low flow zone for checking the existence of the achievement of the 100% sterilizing power for each sterilizer and conducting experiments in high flow to identify differences with sterilizing agent without sterilization blind spot, the analysis was conducted with the simultaneous sampling for each condition at Gwangju Metropolitan Environmental Environment Research Institute and the affiliated laboratory, and to obtain the reliability of the experiment, our company sampled five samples and analyzed the three samples, excluding one with the highest and lowest value. The test device for comparing sterilizing effects owing to presence of blindspots of sterilization

The test device for comparing sterilizing effects owing to presence of blindspots of sterilization

Comparison of sterilization rates in high-flow areas for blind spots of ultraviolet irradiation

| Water Source (CFU/㎖) Dischraged Water |

Influx (ℓ/min) |

Sterilizer with Structure of Separate Respective Sterilizing Part | Sterilizer with Original All-in-one Structure | Note | ||

|---|---|---|---|---|---|---|

| (CFU/㎖) | Sterilization Rate(%) | (CFU/㎖) | Sterilization Rate(%) | |||

| 2,100 (2014/01/06) |

140 | 130 | 93.8 | 150 | 92.9 | Gwangju Health Research Institute |

| 180 | 170 | 91.9 | 280 | 86.7 | ||

| 220 | 340 | 83.8 | 660 | 68.6 | ||

| 2,600 (2014/01/06) |

140 | 160 | 93.8 | 170 | 93.5 | S&P Environment Laboratory |

| 180 | 220 | 91.5 | 460 | 82.3 | ||

| 220 | 310 | 88.1 | 780 | 70.0 | ||

The sterilizing apparatus of an existing all-in-one type show large dynamic range of flow rate according to the flow when there is large amount of sterilizing device flow, and that of the the sterilizing apparatus with an individual salgyunbu structure can be seen to be small, and the table below compared sterilizing power with flowing sewage effluent in low amount of flow in the same condition to check the possibility of achieving 100 % sterilization of sterilizing apparatus in UV irradiation blind spot, and in the case of sterilizing agent without sterilizing blind spot, 100 % sterilization was achieved below 50 ℓ /min, but sterilizing device with sterilization blind spot could not sterilize 100 % in the low amount of flow area.

Comparion between sterilizer’s accomplishments of 100% sterilizations in low-flow areas

| Water Source (CFU/㎖) Dischraged Water |

Influx (ℓ/min) |

Sterilizer with no blind spots of sterilization | Sterilizer with blind spots of sterilization | Note | ||

|---|---|---|---|---|---|---|

| (CFU/㎖) | Sterilization Rate(%) | (CFU/㎖) | Sterilization Rate(%) | |||

| 3,000 (2013/12/10) |

40 | 0 | 100 | 3 | 99.9 | S&P Environment Laboratory |

| 50 | 0 | 100 | 4 | 99.9 | ||

| 60 | 5 | 99.8 | 9 | 99.7 | ||

| 140 | 80 | 97.3 | 110 | 96.3 | ||

| 180 | 300 | 90.0 | 480 | 83.3 | ||

| 220 | 380 | 86.7 | 1,000 | 66.7 | ||