- Business field

- seaweed processing water purifier

seaweed processing water purifier

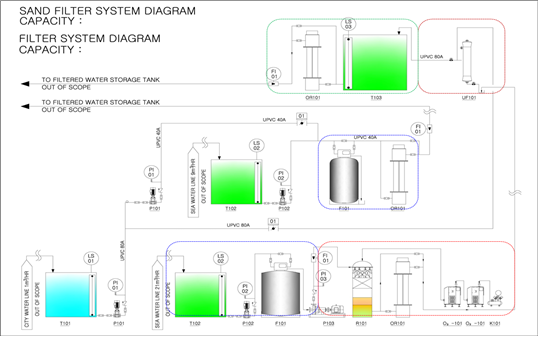

In consideration of the distinctive laver-processing industry, we invented and have provided the purifying system that processes water into drinking one, according to the water quality standards for private waterworks determined by Quality Control Act or Food Sanitation Act.

Some algae, such as dried laver and seaweed, are located mostly on coastal beaches, because it needs seawater and groundwater in processing progress. However, ground water of coastal areas tends to contain salt water, so it is not easy to develop groundwater, and the tap water containing disinfectants has concerns about deterioration of the quality of seaweeds, in addition, if using tap water as processing water, excessive use of water can cause high cost of tap water and sewage fees, and it becomes a reason of the rise of manufacturing cost.

Unlike ground water, surface water like stream water and reservoir contains impurities like germs, turbidity, chromaticity, odor, and other organisms, so it can be used as processing water for seaweeds after being purified hygienically using water purifier according to the standard of water quality.

- Precise filtration system for improvement of turbidity The step to remove dissolved iron, manganese, and turbidity causing substances that affects turbidity by converting to insoluble oxide in the process of the advanced oxidation process, and purify to turbidity standard of 0.2~0.5 NTU.

- Chromaticity, taste, odor removing system The chromaticity, odors, taste and other organisms in the surface water that affect the color of water can be purified by oxidizing with ozone and OH-radical, or adsorption remove with activated charcoal. For water containing manganese and iron, in the ozone or advanced oxidation process to remove chromaticity and odor, converted to insoluble oxidized steel or manganese oxide, and rather can change the color of the water to black or red. In such cases, the removal is possible by installing the filter system in the latter part.

- Sterilizing process system to prevent the contamination of organisms

The dried laver manufacturing process supply sterilized water only by installing sterilizing device right before the manufacturing process to minimize the contamination of the organisms of processed water, because laver processing has the characteristic of using reserved processed water.

마른 김 가공용수 정수시스템

마른 김 가공용수 정수시스템

마른 김 가공용수 정수 파이롯트 시스템

마른 김 가공용수 정수 파이롯트 시스템

- 거품제거시스템

The foam produced by the mixer and aging of the dried laver process is a high viscous and not easily removed, and because of the abundance of nutrients, germs tend to grow easily, and the resulting bubbles stay within the process and serve as germs supplying germs and becoming the main reason of why germs are being overly detected in dried laver.

Some use a defoaming agent(소포제) to remove bubbles, but the use of it may cause damage to the image of the natural laver, even when it’s a additives for use in food, and it can rather cause the increasing of the germs due to poor management.

The bubbles look dark green when mixed with the tiny pieces of laver, and it can make the processing seem unhygienic. The discharged wastewater also causes contamination due to the occurrence of bubbles, which can worse the view and become a cause of the odor when temperature arises.

Our company removed bubbles emerged in dried laver process by applying photocatalytic OH-radical water for the cleanliness of factory and the decrease of the number of the germs, resulting in the improvement of the hygiene of the dried laver producing process and decline of the germs found in the dried laver.

마른 김 가공공정의 거품발생에 따른 위생상태 불량

마른 김 가공공정의 거품발생에 따른 위생상태 불량